| Architecture planning and Geomantic Department. |

| Special thanks to Mr. John Coetzee from Cape Town University. |

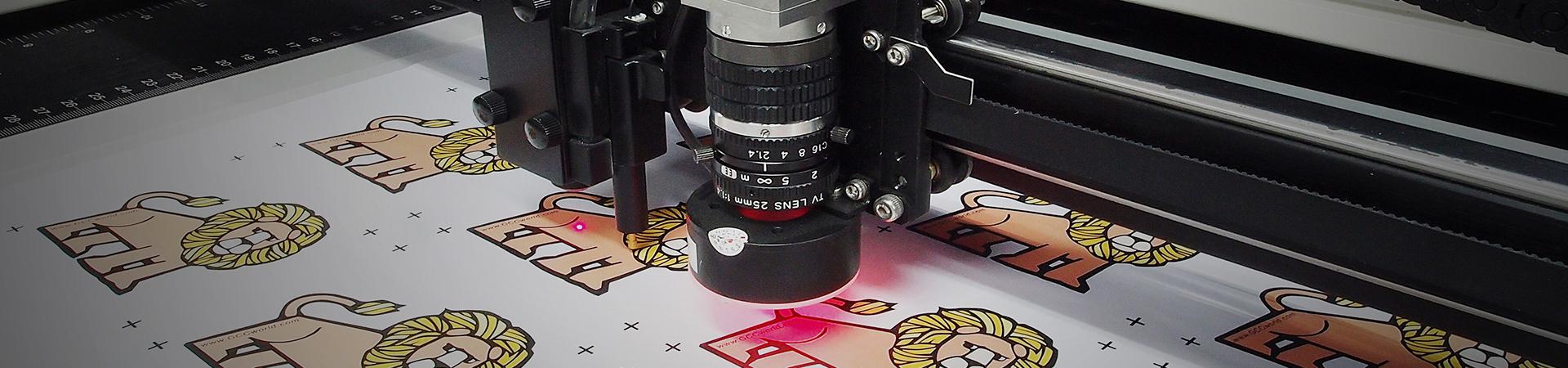

| This lab mainly supports the Architecture department but also works hand in hand with the civil and mechanical engineering workshop. There are 4 GCC laser machines installed in the Lab, 2 units of Spirit GX 60 Watt laser engravers, and one X500 100 Watt laser cutter and FMC270 fiber 200 Watt laser marker. John's lab has also got 3 D printers, CNC routers, printing and wood working machines to assist and support students with their projects. There are over 400 architecture students in this department and work on a booking system between 9:00 and 16:00 each day. Each slot is 1/2 hour and each student is allowed to book maximum 2 time slots per week. The laser machines are always fully booked. Friday afternoons the department closes early for general cleaning and maintenance to the lasers to keep them in top working condition. |

|

| GCC LaserPro’s reliable and stable laser machines are one of the best investments for the university since these machines are fully booked and have been working including Saturdays and Sundays for the past few years. The university has great faith in GCC LaserPro so they have kept purchasing GCC machines that they also think GCC Laser as the "Rolls Royce" of lasers. |

| The relationship between the University of Cape Town and Gencotech can be traced back to 6 years ago when the department looked for a suitable supplier of laser machine. The department staff were very impressed with Gencoteth’s professional service. The department purchased its first GCC LaserPro Spirit GX 60 Watt roughly 5 years ago; with an increase in demand they purchased the second Spirit GLS 3 years ago and X500 and FMC270 in 2014. Whenever the university encounters any problems about machines, Mr. Nardus Mouton of Gencotech responses immediately to assist them to solve issues and ensures that machines can be operated perfectly as soon as possible; this is how the relationships is built. |

|

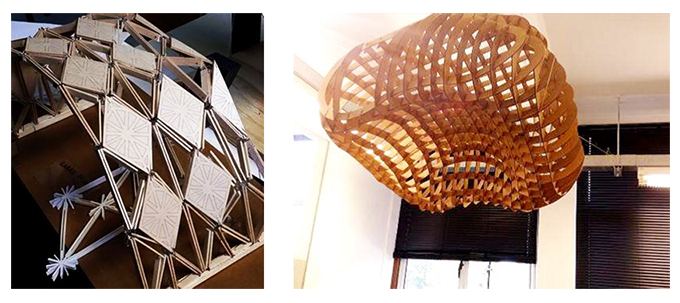

| Students have projects to design and present. The old fashioned way is to cut the model by hand yet this is time-consuming and doesn’t look professional. With Laser, the cutting edges are precise and models look perfect. In addition, GCC LaserPro’s drivers are easy to use and able to be applied to other GCC LaserPro machines so once users have learnt the driver got used to it; they don't want to change to any other driver. |

| This is THE FUTURE,” said a local architect from Cape Town who paid the University for using the laser engraver with time-of-use rate. The University will be purchasing more laser machines in the near future and convince their students do the same after they graduate. The major applications are for building and furniture. |

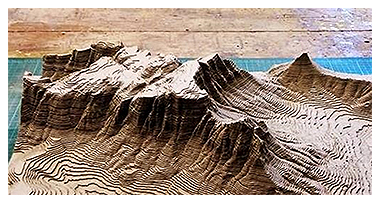

| The Lab provides laser machines and the technology and students have to prepare their own materials and consumables. The most common materials are cardboard, paper, droplet (thick board with white coated film) as well as MDF. The most used material is droplet with 1.2, 2, 2.5 mm specification. The laser cutter works on a 2 D object, they can also use the laser cutter to made 3D models. Students made the famous Cape Town Table Mountain in 3D. Slice per slice of paper was cut by a GCC laser cutter and assembled together. |

|

| Students can also complete their 3D models a 3D printer; however, the problem of a 3D printer is that the consumables are very expensive which not all students can afford; also the printing time is very long and it is difficult to maintain consistency and cleaning of the pump is time consuming as well. Although there are cheaper 3D printers available in the market, but the quality is rough and once again the cleaning of the machine takes time. |

| With more demand for metal cutting not only for the architecture department but also the mechanical department, the University decided to invest a FMC metal cutting machine from GCC which is more user-friendly to operate than a water jet or a plasma cutter. The compact size of the machine can meet the demand for the application needed. The most common cutting size is 1mm to 1.5mm of stainless steel. |

| In conclusion, GCC LaserPro’s reliable laser machines and after-sales service from Gencotech have made the University of Cape Town very happy and satisfied. |

| If you have your own successful stories with GCC laser machines or any other GCC products, we welcome and encourage you to share them with us. Email your photos/videos and stories at to news@gccworld.com now! *Please refrain from reproducing or distributing this article without obtaining permission from GCC. |

Cape Town University architecture application lab | GCC: Laser Machines Leader Since 1989

English

Success Story