Приложения THERMARK | GCC лазерные гравировальные и режущие машины

To elevate product value and recognition, letterings or graphics are engraved onto precision mechanics, parts and objects to add product distinction. Presently the YAG or YVO4 Laser has been utilized to engrave on these parts and optimally delivers meticulous results. However, the market price of YAG or YVO4 Laser is much higher than the CO2 Laser which can be a considerable heavy burden for some manufacturers; if there is a cheaper CO2 laser option available to take the place of YAG and YVO4 laser, it will certainly be a popular alternative.

Using the CO2 laser to engrave on metals is practicable, as in our previous Showcase we had already exhibited applications using the CO2 laser to engrave on metals. Therefore, operators can take the advantage of adapting a special THERMARK substance with their CO2 laser, which in due course will also achieve results and performances matching the YAG and YVO4 Laser.

The LaserPro Application Lab acquired assorted paints provided by THERMARK http://www.thermark.com/; these THERMARK paints can be used on stainless steel, iron, copper, metal, lead, titanium, nickel and other metallic substance and also produce exciting color creations on glasses.

The LaserPro Application Lab will now demonstrate with THERMARK to create samples, exhibiting distinguishing results with different THERARK paints. Please refer to illustrative examples below for more information.

Steps:

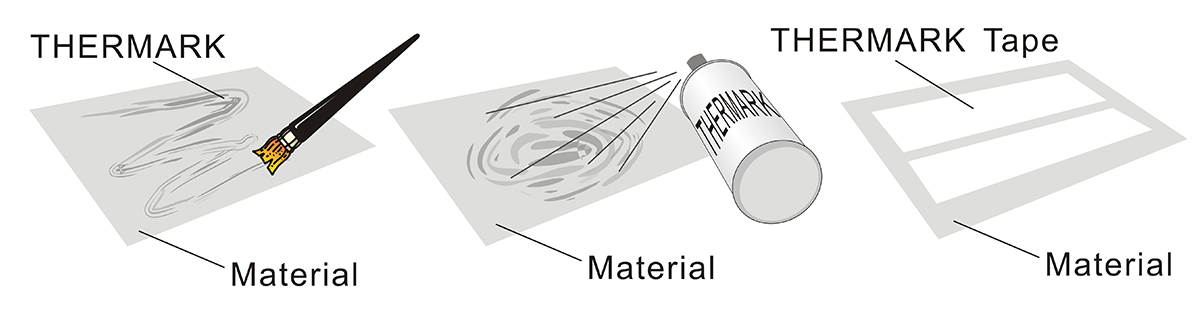

- Select suitable THERMARK in terms of resource materials chosen, then apply THERMARK by methods of painting, spraying or paste on to designated engraving position.

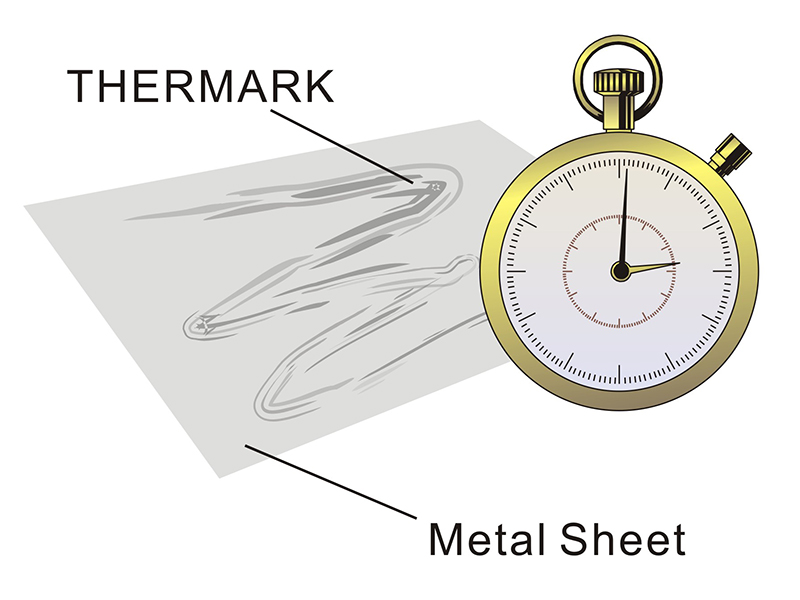

- After THERMARK is dry (every THERMARK dries up at different speeds, averaging between 1-3 minutes), then place into the machine as engraving will follow when ready.

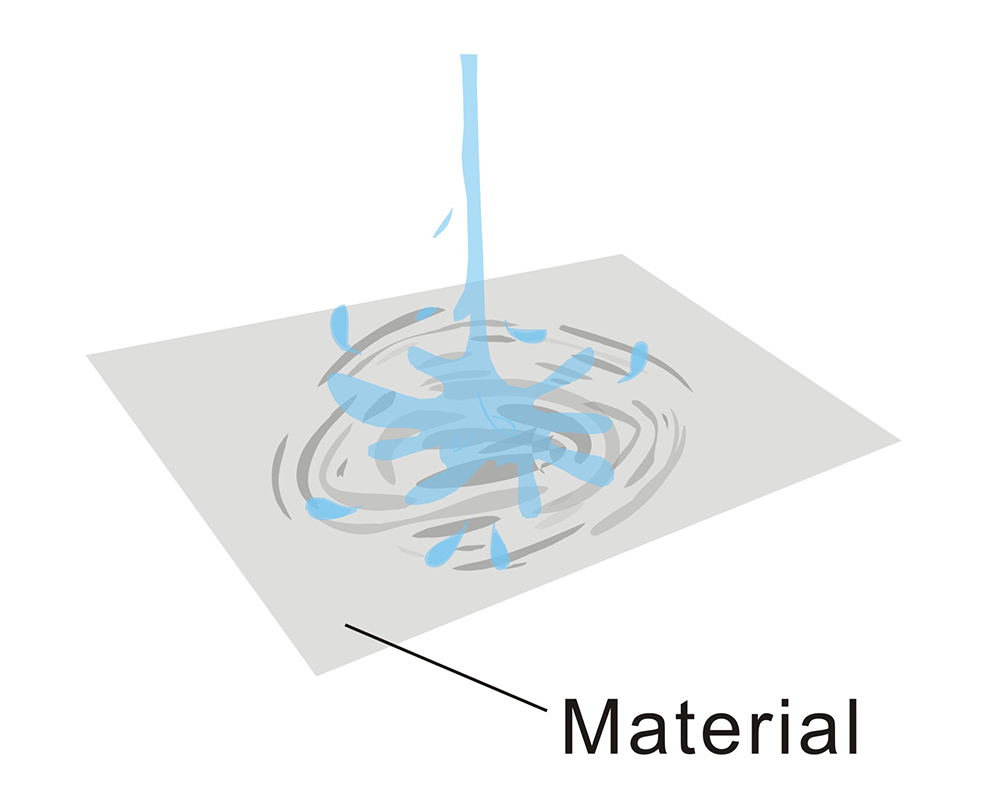

- After engraving, use water to rinse clear the THERMARK residue.

- Sample

Stainless engraving sample

Glass engraving sample

Engraving parameters:

| Spirit 60W | ||||

| Speed | Power | dpi | ppi | Other |

| 10% | 70% | 500 | 400 | No |

Tips:

• The amount of THERMARK applied should not be too excessive, the application action should be even and smooth; any uneven application may cause imperfections to the final product.

• Parameters should be moderately adjusted when different power output is used.